We live progress. With sustainability.

With extrusion processes that are as pioneering as they are environmentally conscious. Our extruders are excellently suited for recycling processed plastic. This makes them an important player in the recycling loop.

Why is this approach more important today than ever?

Because global plastic consumption will increase to 400 million tons per year by 2030 and plastic is too valuable to have just one life cycle.

Tailor-made solutions for advanced recycling

A machine does not find the answers to the challenges of today and tomorrow.

It's the brains: our engineers, application technicians and process specialists.

Their formula for success for the smart recycling of sustainable materials:

Know-how, sound experience and smart technology.

The result offers a wide range of possibilities. We support you in the development and implementation of your recycling processes with our process expertise:

Tailored to your individual needs.

Designed for efficient

plastics recycling

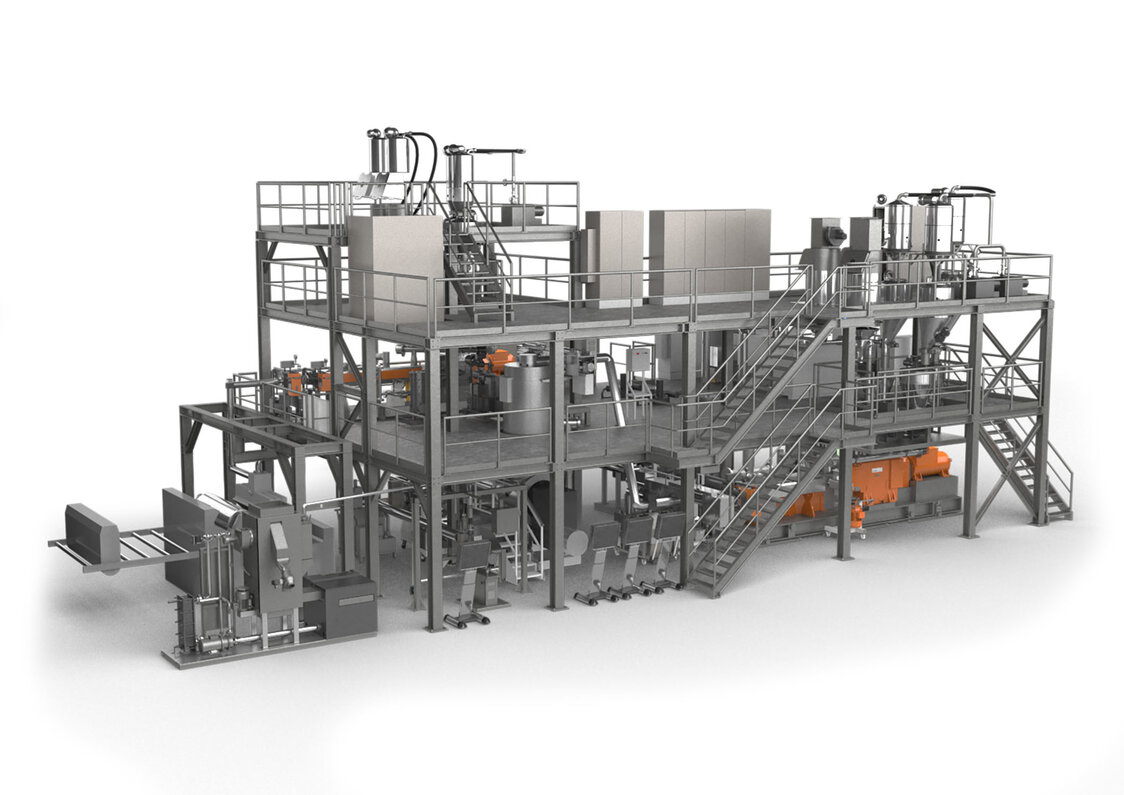

We develop systems for our customers that focus on plastics recycling.

Depending on the design, our systems are suitable for the entire spectrum of recyclable materials - from unmixed production rejects to post-consumer collected goods.

See for yourself:

That is how we “produce” sustainability - a few examples

Preparation or recycling of

- PP (polypropylene) and PE (polyethylene)

- PET (polyethylene terephthalate)

- Engineering plastics, such as

- PC-ABS (polycarbonate/acrylonitrile butadiene styrene) for interior components in the automotive sector - or for electrical appliances,

- PA (polyamide) in the electrical appliances sector,

- POM (polyoxymethylene) in machine, vehicle and appliance construction

- Rubber (e.g. contained in used tires)

With our process engineering expertise in mechanical and chemical recycling, we provide comprehensive support in the recycling of your materials.

Features and advantages of our ZSE MAXX extruders in recycling

Compact design

Minimal space requirement and low space consumption.

Top quality

Ideal for the highest quality requirements thanks to inline control.

High flexibility

Used for a wide variety of plastics such as PP, PE, PA, POM etc.

Food safe

Production of food-grade multilayer and strip films from up to 100% recycled material.

Efficient upcycling

Processing of PET recyclates of various input qualities.

Twin-screw extruders offer a number of decisive advantages.

Convince yourself:

Optimum recycling results

With the Leistritz elongational rheometer, you can control the melt flow rate in plastics recycling and thus achieve a high output quality. Take a look at the case study on MFR value control!

recycling-loopPlastic recycling loop - extrusion with responsibility

Discover our remanufacturing processes - for your sustainable production.

Cost-efficient recycling and upcycling is indispensable in today's product utilization and reprocessing cycle. Cost-effectiveness and sustainability can be combined to create a closed value-added cycle.

We open up new perspectives for you:

With our extrusion solutions, we are your specialist for post-industrial recycling and post-consumer recycling.

Optimum recycling results

With the Leistritz elongational rheometer you can control the melt flow rate in plastics recycling and thus achieve a high output quality. Have a look at the case study on MFR value control!

Sustainable also works for Design@Home

A special extrusion process makes it possible to process new materials in flooring. Chlorine-free, PVC-free, without plasticizers and without environmentally harmful ingredients.

Online measurement of shear and elongational viscosity in real time!

Find out how you can ensure quality management during the extrusion process with the Leistritz inline elongational rheometer.

Turnkey solutions: Tailor-made, individual & ready to use.

Benefit from unique expertise, comprehensive technical knowledge and reliable implementation skills.

Wir sind für Sie da

Sie haben Fragen? Unsere Ansprechpartner freuen sich auf Ihre Nachricht und helfen Ihnen gerne weiter.

Roberto Freire Matteucci

Global Sales Director Recycling & Biopolymers

Leistritz Extrusionstechnik GmbH

T+49 911 4306-327